| Forming Area |

|---|

| 700 x 420 mm |

| Mould Con. Area |

| 1010 x 460 mm |

We can also produce according to our clients’ special demand and their needs.

Our machines has a world-class technology with improved software. As a result of this, we produces our machines that show highest performance in its classification.

Our machines are fully equipped with forming, cutting and stacking features. The adjustments of the machine can be controlled easily with touch screen and it also has variable options according to our valued clients’ needs.

The manufacture of disposable cups, plates and lids with our new design thermoforming machine is more economical and faster. Furthermore we have designed the bottom mould table’s tilting as it will be optimum, in this way, our machine has more time for forming.

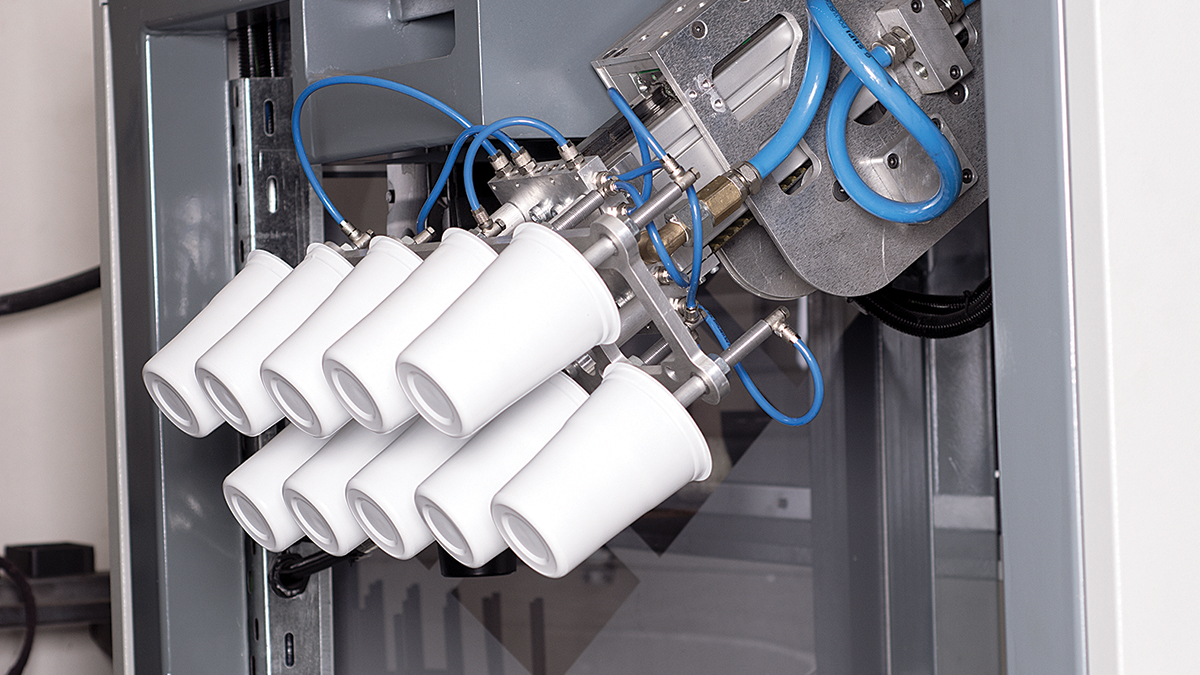

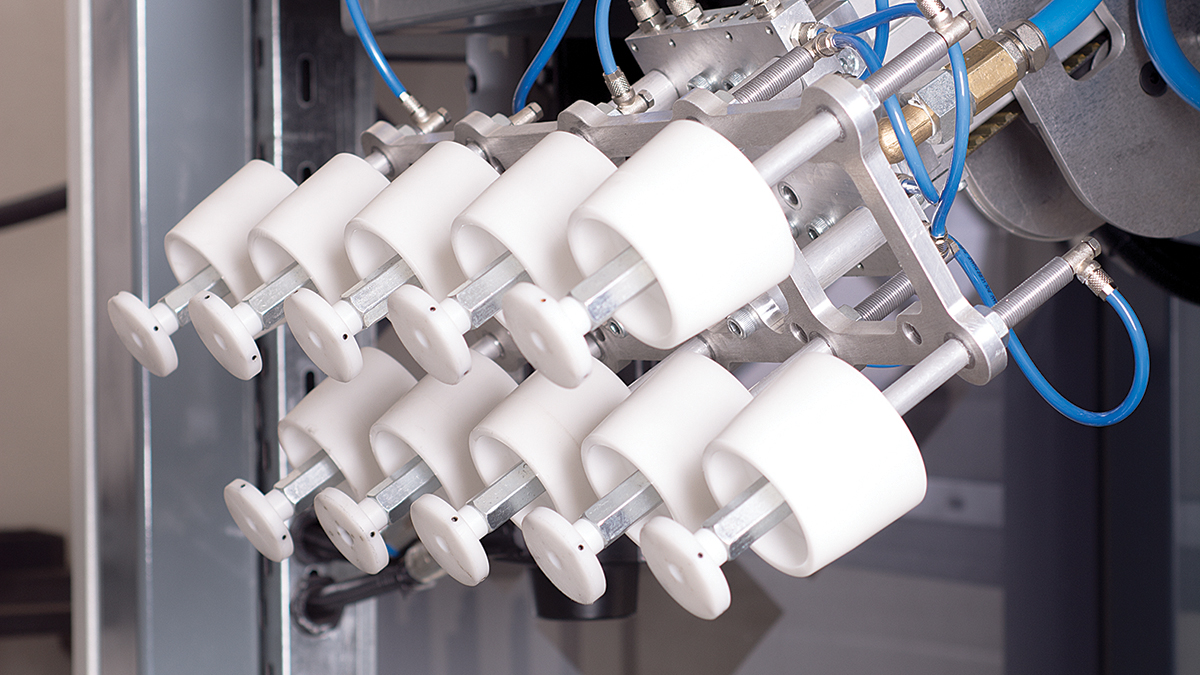

We have designed stacker system to pack products in different designs by using robatic vacuum. We didn’t use brush system, therefore we prevent products’ deformation. We present our new design thermoforming machine to our valued customers’ serve after long term test phase and R&D studies.

We tried to create the most ergonomic and easy to use a machine in the direction of in coming request. We always take into consideration your suggestion and your special demand to develop our machines.

We wish you will be satisfied…

- Fast and flexible thermoforming system

- It is different from the other tilting thermoforming machines with the used technology.

- Simple operation with minimum staff cost.

- The possibility of producing quality and on time for the small and medium size product.

- Mould change period is faster so it can be given quick response to market needs.

- Easier mould exchange possibility with the lifter which is situated on the machine.

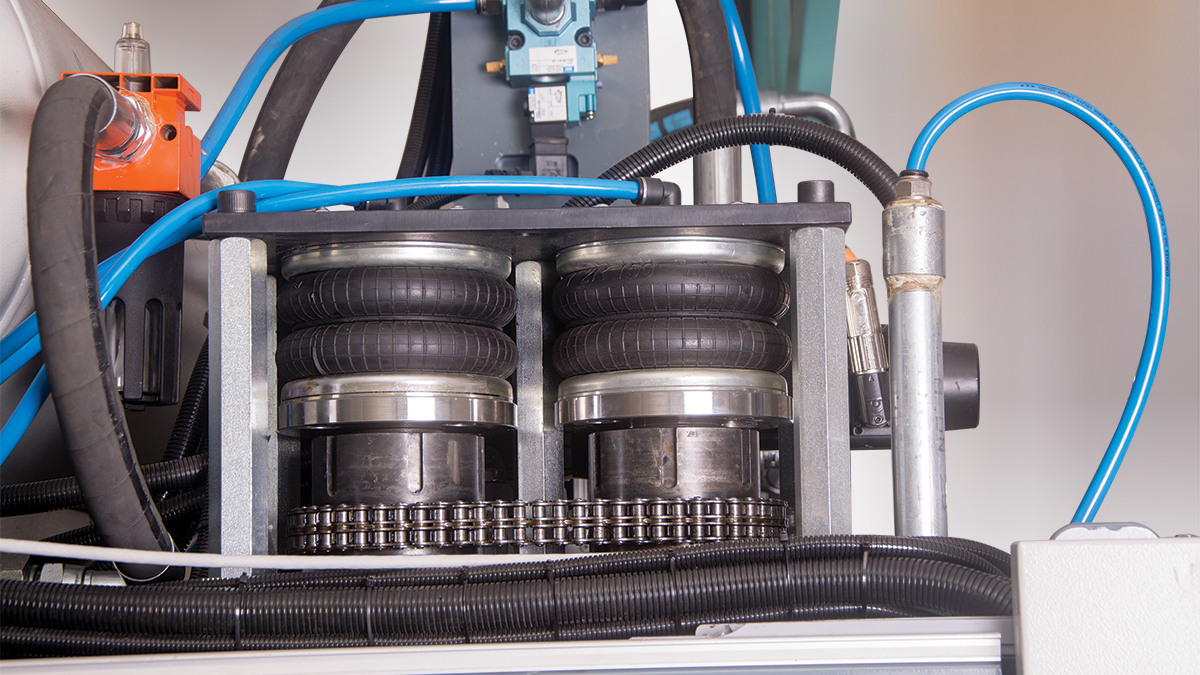

- Electronic cam system except mechanical cam electronic cam system supplies high quality production for different weight material, it also supplies the product to cool in the mould and it gains cycle time.

- Easy adjustable plug system at the desired depth to make the products stretch.

- Economic outturn, fertility, high productivity and low energy consumption thanks to regenerative units.

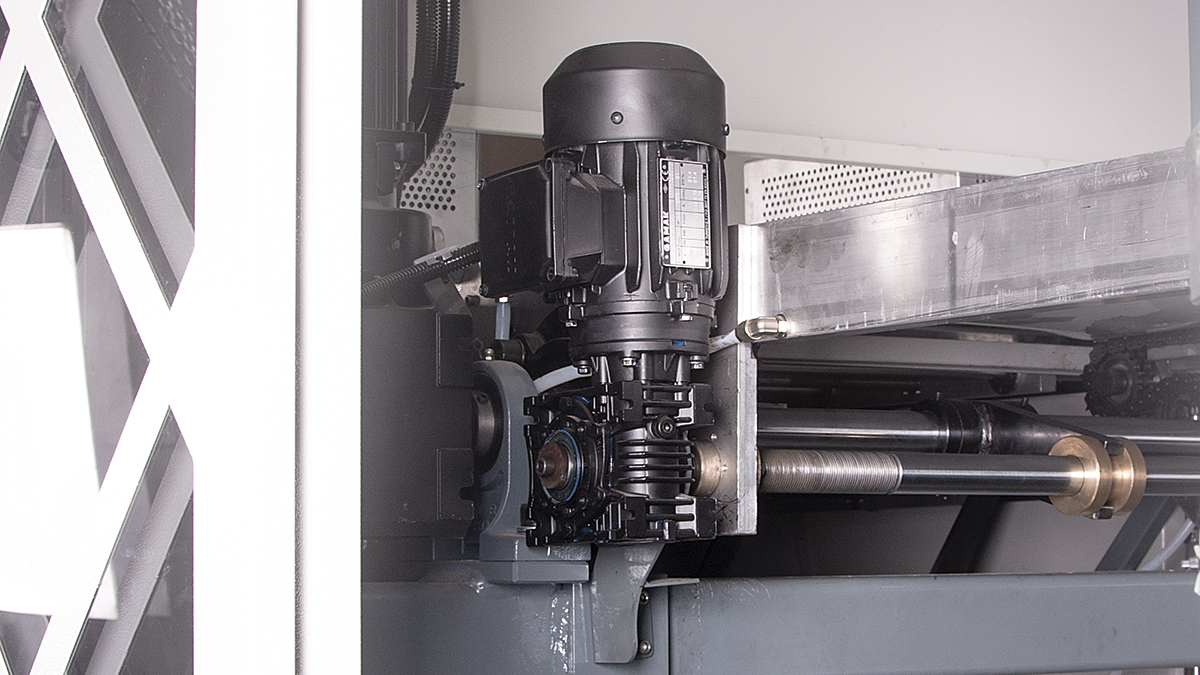

- Smart Servo and motion system

- Airconditioner for electric cabin.

- User focused easy handling and moveable control panel

- Online remote access possibility for automation system

- Latest generation software program

- 15” colorful touch screen and operating system

- Control panel with Turkish-English language option

- Understandable screen menu guidelines

- The ability to create a separate recipe for each product and the ability to memorize all recipe

- Temperature warning indicator when the machine waits for a while

- The control and follow-up of heats by screen

- The ability of adjusting chain arm and sheet entry according to different mould height.

- The ability of making adjustment of sheet's width and stretch

- Heating system at the plate entry for the easily sinking of the chain

- Warning laser sensor for against plate sagging

- Plug and mould heating property for shaping at the desired feature at rst

- At first until the desired quality product is formed, our machine doesn’t cut the sheet ( the products doesn’t fall the ground thus it supplies to prevent the loss of raw materials)

- Mould temperature checking system to supply stable and safe operation

- Air, vacuum and water indicator

- Air, vacuum and water filters

- Vacuum pump

- Safe operation with the low air pressure warning control

- Measurement of mould temperatures, facility of monitoring from the screen and water control with automatic value system

- Automatic lubrication system and low maintanence thanks to optimal accessibility to all critical areas

- Automatic chain lubrication system

- Easy access to all parts of the machine ( It provides to facilitate cleaning and maintenance works)

- High production variety and exibility ( the possibility of production of cubs, lids and plates)

- Counting system that supplies stacking different products

English

English  Türkçe

Türkçe